The Simandou iron ore project is one of the largest unexploited high-grade iron ore deposits in the world. With the project’s development reaching an important milestone in March this year, the project’s partners have been able to kick off with development work, including support from the government of Guinea with defined requirements for the start of production.

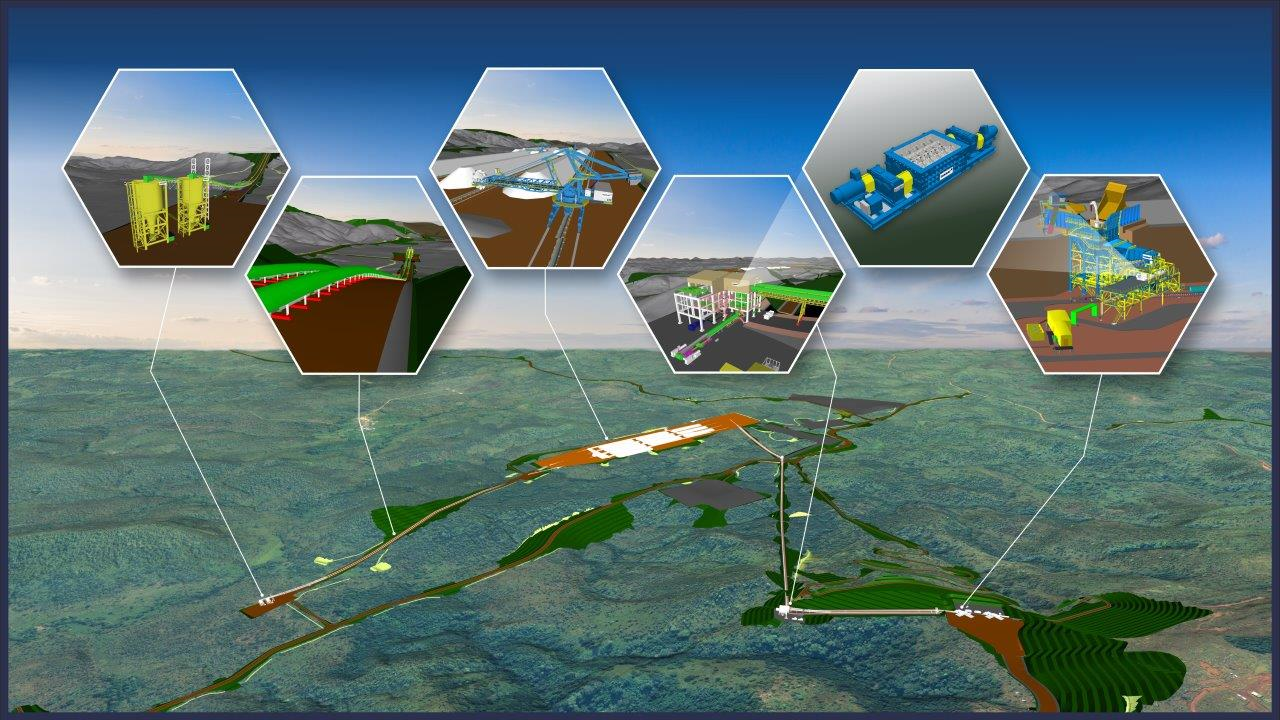

The contract entails the design, fabrication and delivery of an advanced and integrated IPCC and material handling system.

Highlights include:

- Two primary IPCC systems incorporating two TAKRAF X-TREME class sizers to crush extracted ore received by truck

- A secondary In Pit Secondary Crushing & Conveying (IPSCC) system incorporating four TAKRAF sizers for further ore processing

- Two rail mounted stackers for ore stockpiling

- Two rail mounted reclaimers for ore reclaiming

- Two wagon loading stations with buffer silos

- A complex conveyor system with transfer stations for the above equipment, including a technically sophisticated long downhill conveyor between the secondary IPSCC system and the stockyard

- Electrical and control equipment and stockyard auxiliaries

In order to achieve the desired annual production rate the crushing system has been sized with a design capacity of up to 13,200 t/h. Please read more: In Pit Crushing & Conveying (IPCC) and material handling system contract for TAKRAF in Guinea – TAKRAF GmbH