Due to the depletion of manganese ore reserves in the Kazmarganets mine management of TNK Kazchrome JSC as part of ERG, mining work has been stopped. Following the policy of caring for natural resources, the enterprise will continue to work in the field of processing previously mined ores, using new modern enrichment technologies. Most of the employees released by the cessation of production will be employed in other ERG divisions.

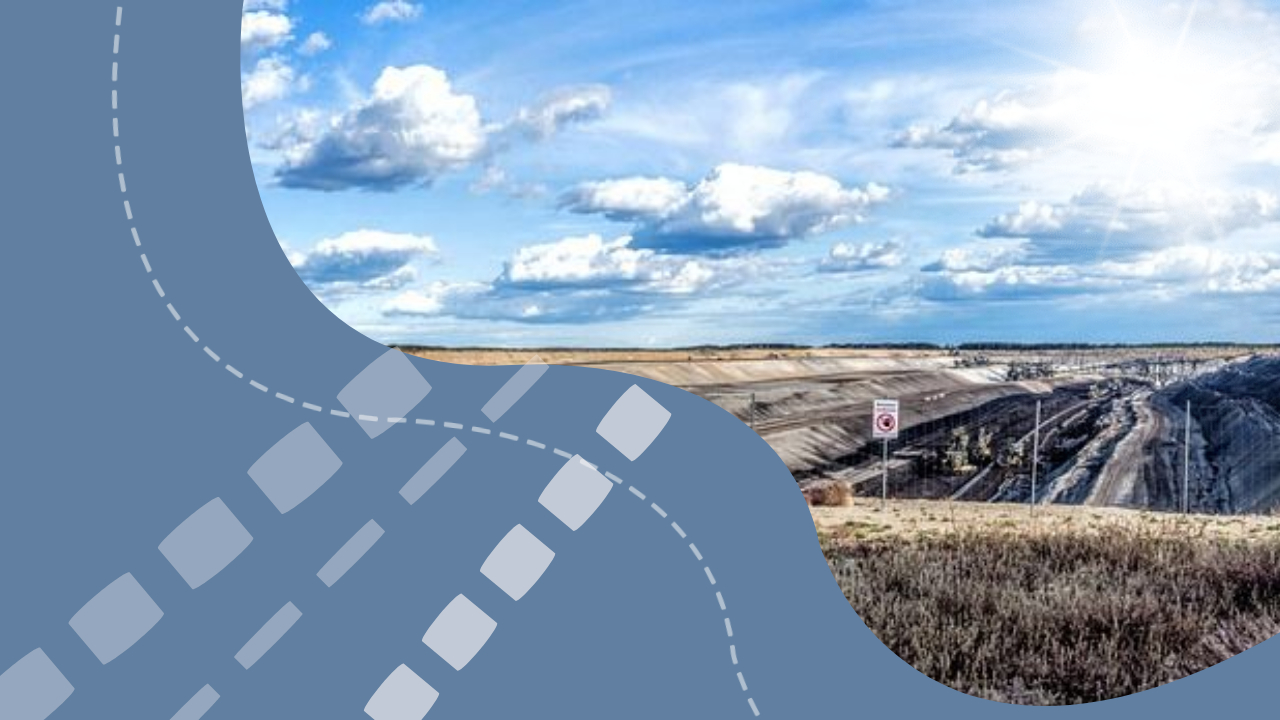

The history of the Kazmarganets mine management begins in 1997, when the Aksu Ferroalloy Plant, another branch of TNK Kazchrome JSC, began developing a manganese ore deposit in the Nura district of the Karaganda region. In the first years, the infrastructure at the Tur mine was intensively developed, a rotation camp for workers was built, mining and transportation equipment was purchased, and the technology for obtaining manganese concentrate for ferroalloy production was being developed. In 2004, the division was reorganized into an independent asset of TNK Kazchrome JSC. The quarry was mined using open pit mining. Over 26 years, employees of the mine management worked almost 76 million m³ of rock mass and extracted 13.7 million tons of manganese ore.

At the time of the cessation of ore mining, the mine department employed 413 employees, a little more than a hundred of them were laid off. Work is now underway to employ them at other ERG enterprises.

“The question of stopping the mining process at the mine has been raised for years, so we were systematically preparing for this stage,” notes Kazchrome General Director Sergei Prokopyev. – First of all, we resolved the issue with people with whom we had worked together for many years. At first, this was work to optimize the number of employees through vacancies, now we are working on employing the released personnel at enterprises within the Group. Since we are talking mainly about employees working on a rotational basis, similar assets are considered – JSC Shubarkol Komir, JSC Manganese Zhairema, Donskoy Mining and Processing Plant.

At the same time, the mine management will continue its work, focusing on the processing of previously mined reserves, as well as the enrichment of small ore screenings.

“Following its mission to carefully use the earth’s potential, ERG pays special attention to waste recycling,” adds Sergey Prokopyev. – We cannot afford a barbaric attitude towards natural resources. There are enough innovative technologies and new engineering solutions that ensure reasonable handling of raw materials. And we will use them, thus ensuring the rational use of natural resources. We will use the same careful approach to restore the damaged landscapes of the area as much as possible.

To eliminate the consequences of mining activities at the Tur mine, in accordance with legal requirements, a project has been developed for the reclamation of land plots affected by the mining process. This is about 516 hectares. Their reclamation will begin in 2024, then the soil will be covered with a fertile layer and sown with grass.